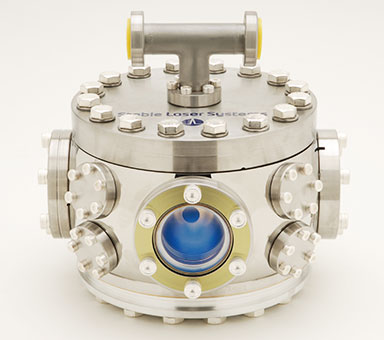

Spherical Cavity Housings: VH 6300

Our vacuum housings for spherical cavities harness the inherent stability of this compact geometry.

We use our own unique mounts developed through extensive finite element modeling and design iterations. We’ve discovered the best materials, mounting, and common-mode techniques to reduce thermal deformation for maximum frequency stability over the widest possible operating temperature range, also damping vibrations to reduce ambient acoustic noise signatures.

Ultimate portability, maximum performance

Performance & Specs

| Frequency Drift | < 30 kHz/day at zero crossing temperature, 1550 nm |

| Temperature Drift | < 5 mK/°C |

| Temperature Control Range | 5 – 50°C |

| Thermal Time Constant | 4 hours |

| Achievable Pressure | < 10-6 Torr |

| Vacuum can | 316L Stainless steel, with 3 adjustable-height base clamps |

| Viewports | AR coated windows angled at 2° with respect to can axis |

| Fittings | Stainless steel tee with two Conflat fittings for ion pump & valve |

| Temperature Control | 6 Ω heaters as standard |

| Thermistors | Two: 10 kΩ @ 25°C |

| Weight | 6 kg |

Features

- < 5 mK/°C temperature drift over a wide operating temperature range (5 – 50°C)

- Lowest thermal insulation leakage housing: < 0.25 W/°C

- Diametric and tetrahedral mounting options

- Highly portable; cavity remains aligned in transport

- Cavity housing can be optimized for commercially available or custom cavity designs

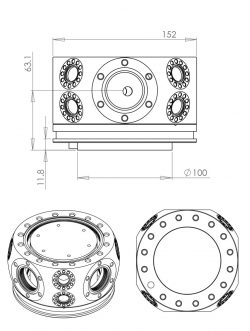

Engineering Diagram

Customization Options

- Adaptation for spherical cavities up to 50 mm in size

- Yoke, diametrically constrained, and tetrahedral mounting methods

- Dual stage temperature stabilization; multistage available upon request

- Detailed characterization of acceleration coefficient